| Jumbo roll width: | |

|---|---|

| Jumbo roll diameter: | |

| Embossing style: | |

| Glue lamination system: | |

| Speed: | |

| Qty of jumbo roll stand: | |

| Counting : | |

| Availability: | |

| Quantity: | |

XY-BT-288

XINYUN

8441809000

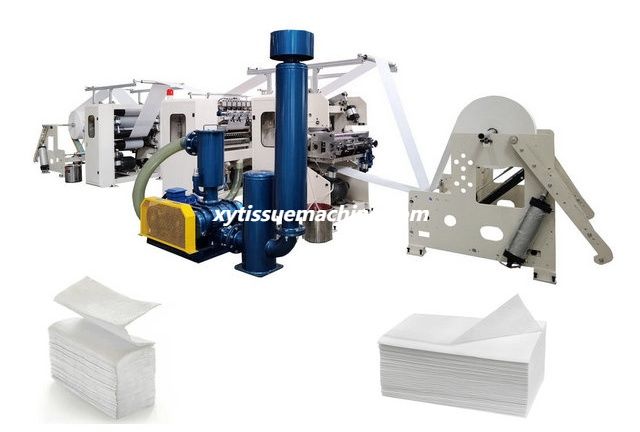

The Automatic Interfold Glue Lamination Hand Towel Facial Tissue Paper Machine is a cutting-edge solution for producing premium interfolded tissues, combining precision lamination, high-speed folding, and automatic glue application. Engineered for both hand towels and facial tissues, this machine processes 1-ply to 4-ply materials with customizable softness and strength, delivering 150-200 sheets per minute with uniform interfolded structure. Its advanced glue lamination system ensures secure layer bonding, ideal for high-moisture environments and luxury tissue products.

Dual-Lane Interfold Technology:

Patented folding drums create "C-fold" or "Z-fold" patterns with 99.8% accuracy, supporting sheet sizes from 15x15cm to 30x30cm.

Adjustable glue application nozzles (0.1-0.5mm precision) bond multiple plies without residue, enhancing tensile strength by 25% for wet-use scenarios.

Intelligent Lamination Control:

Servo-driven unwind stations with tension sensors (±1N) prevent web breakage during multi-layer lamination of tissue, non-woven, or PE film.

Infrared moisture sensors monitor glue curing in real-time, ensuring adhesion meets ASTM D903 standards for wet tensile strength.

High-Speed Production System:

500mm-wide lamination rollers operate at 200m/min, with quick-change tooling for switching between hand towel (200-sheet packs) and facial tissue (100-sheet packs).

Automatic edge trimming system reduces material waste to <1%, significantly improving yield compared to manual processes.

Hygienic Design:

Stainless steel contact surfaces with FDA-compliant food-grade lubricants, suitable for direct skin contact and medical-grade tissue production.

Negative-pressure dust collection system maintains a clean production environment, meeting ISO 14644-1 class 8 cleanliness standards.

Hospitality & Healthcare: Produces interfolded hand towels for hotel restrooms, hospital wards, and surgical clinics, with optional antibacterial lamination.

Household Facial Tissues: Manufactures soft, multi-ply facial tissues for daily use, compatible with aloe vera or lotion-infused materials.

Industrial Wipes: Processes heavy-duty interfolded wipes for automotive workshops and cleanrooms, using synthetic blends for oil resistance.

Custom Bonding Solutions: In-house R&D team develops tailor-made glue formulas for specific applications (e.g., low-odor for baby tissues, waterproof for outdoor wipes).

Energy-Efficient Operation: Regenerative drives and LED curing lamps reduce power consumption by 30% compared to conventional lamination machines.

Global Compliance Assurance: Certified to CE, UL, and ISO 9001, with optional NSF/ANSI 61 certification for drinking water contact applications.

Video Link: https://www.youtube.com/watch?v=BlRE_To7OXk

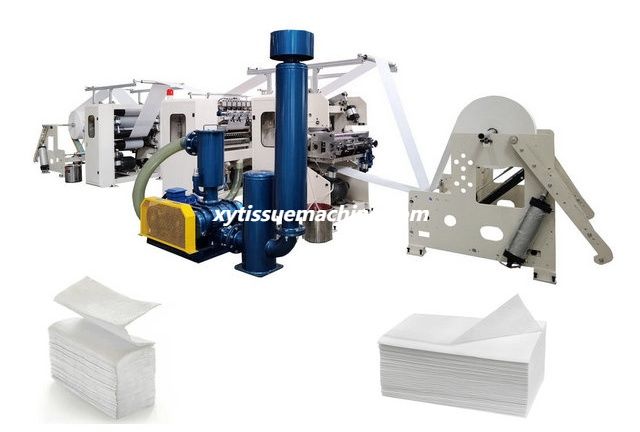

The Automatic Interfold Glue Lamination Hand Towel Facial Tissue Paper Machine is a cutting-edge solution for producing premium interfolded tissues, combining precision lamination, high-speed folding, and automatic glue application. Engineered for both hand towels and facial tissues, this machine processes 1-ply to 4-ply materials with customizable softness and strength, delivering 150-200 sheets per minute with uniform interfolded structure. Its advanced glue lamination system ensures secure layer bonding, ideal for high-moisture environments and luxury tissue products.

Dual-Lane Interfold Technology:

Patented folding drums create "C-fold" or "Z-fold" patterns with 99.8% accuracy, supporting sheet sizes from 15x15cm to 30x30cm.

Adjustable glue application nozzles (0.1-0.5mm precision) bond multiple plies without residue, enhancing tensile strength by 25% for wet-use scenarios.

Intelligent Lamination Control:

Servo-driven unwind stations with tension sensors (±1N) prevent web breakage during multi-layer lamination of tissue, non-woven, or PE film.

Infrared moisture sensors monitor glue curing in real-time, ensuring adhesion meets ASTM D903 standards for wet tensile strength.

High-Speed Production System:

500mm-wide lamination rollers operate at 200m/min, with quick-change tooling for switching between hand towel (200-sheet packs) and facial tissue (100-sheet packs).

Automatic edge trimming system reduces material waste to <1%, significantly improving yield compared to manual processes.

Hygienic Design:

Stainless steel contact surfaces with FDA-compliant food-grade lubricants, suitable for direct skin contact and medical-grade tissue production.

Negative-pressure dust collection system maintains a clean production environment, meeting ISO 14644-1 class 8 cleanliness standards.

Hospitality & Healthcare: Produces interfolded hand towels for hotel restrooms, hospital wards, and surgical clinics, with optional antibacterial lamination.

Household Facial Tissues: Manufactures soft, multi-ply facial tissues for daily use, compatible with aloe vera or lotion-infused materials.

Industrial Wipes: Processes heavy-duty interfolded wipes for automotive workshops and cleanrooms, using synthetic blends for oil resistance.

Custom Bonding Solutions: In-house R&D team develops tailor-made glue formulas for specific applications (e.g., low-odor for baby tissues, waterproof for outdoor wipes).

Energy-Efficient Operation: Regenerative drives and LED curing lamps reduce power consumption by 30% compared to conventional lamination machines.

Global Compliance Assurance: Certified to CE, UL, and ISO 9001, with optional NSF/ANSI 61 certification for drinking water contact applications.

Video Link: https://www.youtube.com/watch?v=BlRE_To7OXk

1610 Enterprise Building, Wanan, Luojiang, Quanzhou, Fujian, China

Phone: +86-13685949824

Whatsapp: +86-13685949824

Email: elaine@xinyun-engine.com