Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

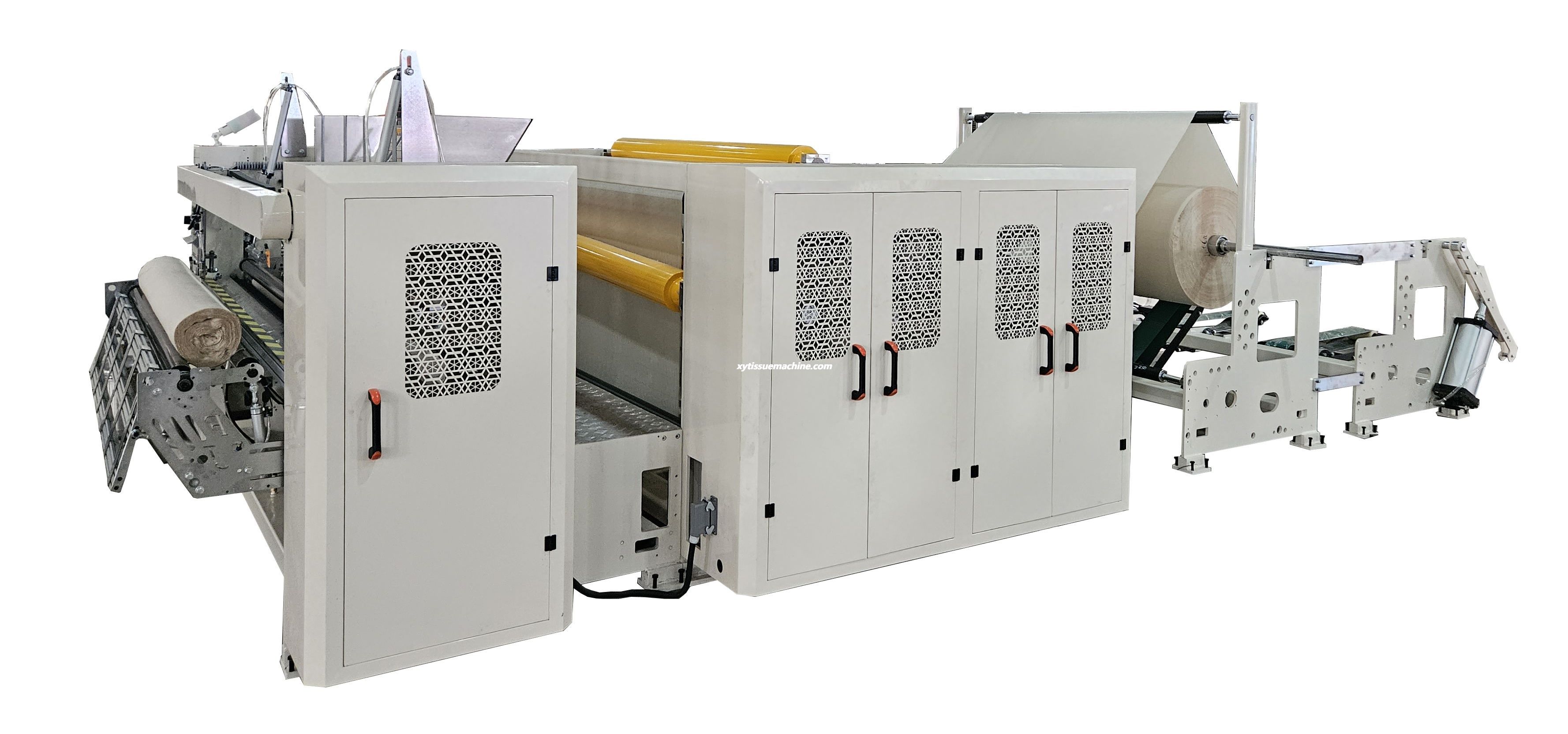

Boosting Production Efficiency with Modern Tissue Making Machines

The tissue manufacturing industry is witnessing a transformative era, driven by the increasing demand for high-quality, sustainable, and cost-effective products. At the heart of this transformation lie modern tissue making machines, designed to enhance production efficiency while minimizing energy consumption and waste.

Tissue production is one of the most energy-intensive processes in the paper industry. A significant portion of energy—often up to 70%—is consumed during the drying phase, while water use and fiber loss also contribute heavily to operational costs. Additionally, inefficiencies caused by machine downtime, web breaks, and inconsistent product quality further reduce profitability. With rising raw material prices and stricter environmental regulations, manufacturers are under increasing pressure to optimize every aspect of their production lines.

Modern tissue making machines feature optimized press sections that improve moisture distribution across the paper web. This leads to more uniform drying and reduces drying time. Enhanced moisture control also helps maintain consistent sheet properties, enabling faster machine speeds without sacrificing quality.

Innovative drying technologies reduce energy consumption while maintaining or improving tissue softness and strength. Improved insulation, heat recovery systems, and refined air flow within drying sections minimize heat loss. These features contribute to significant savings in gas and electricity consumption, directly impacting operational costs.

The integration of automation and intelligent process control systems has revolutionized tissue production. Real-time monitoring of critical parameters such as moisture content, basis weight, and machine speed allows operators to optimize the process continuously. Automated adjustments reduce variability, prevent defects, and increase overall equipment effectiveness (OEE).

Consistent quality is a critical factor in customer satisfaction and brand loyalty. Modern tissue making machines enable manufacturers to produce tissue products with uniform softness, strength, and appearance. Precise control of embossing patterns, fiber distribution, and sheet thickness ensures a premium product that meets consumer expectations.

Additionally, advances in web inspection technology detect and address defects immediately, minimizing waste and rework. This real-time quality assurance supports the production of high-margin tissue products that can command premium prices in the marketplace.

Reducing Waste and Downtime for Greater Profitability

Downtime caused by machine stoppages, web breaks, and maintenance significantly impacts productivity and profitability. Modern tissue machines are designed to minimize these interruptions through:

Improved mechanical reliability and precision components

Automated blade changers and roll splicing to reduce manual intervention

Predictive maintenance capabilities powered by data analytics, allowing preemptive action before failures occur

These improvements result in higher uptime, more consistent output, and reduced operational costs.

In today’s manufacturing landscape, sustainability has evolved from a mere option to a fundamental necessity—especially in the tissue industry, where environmental concerns are increasingly scrutinized by consumers, regulators, and stakeholders alike. Modern tissue making machines are engineered with sustainability at their core, enabling manufacturers to significantly reduce their ecological footprint while maintaining high production standards.

One of the primary ways these advanced machines support sustainability is by reducing energy consumption. The drying and refining stages, historically the most energy-intensive parts of tissue production, have seen remarkable improvements through innovative technologies. Enhanced drying systems with improved heat recovery, optimized air flow, and insulation materials minimize energy waste. Similarly, modern refiners use less power to achieve the same or better fiber quality, drastically cutting electricity consumption. These improvements not only reduce operating costs but also decrease greenhouse gas emissions, contributing to global climate goals.

Another critical environmental benefit comes from minimizing water use. Tissue production traditionally requires vast quantities of water, especially in fiber preparation and web forming. Modern machines incorporate closed-loop water systems, recycling process water to limit fresh water withdrawal. Additionally, optimized fiber processing techniques reduce water usage without compromising sheet quality. These efforts alleviate pressure on local water resources and lower wastewater treatment costs, making production more sustainable and community-friendly.

Reducing raw material waste is equally important in sustainability efforts. Precise process control technologies allow for tighter tolerances and real-time monitoring of parameters such as moisture content, basis weight, and fiber distribution. This means fewer off-spec products and less scrap that would otherwise be discarded or reprocessed. Advanced quality inspection tools identify defects early, preventing defective batches and reducing overall material loss. This efficient use of raw materials not only saves money but also conserves natural resources by maximizing every fiber’s potential.

Beyond these tangible benefits, sustainability initiatives help manufacturers meet increasingly strict regulatory requirements related to energy use, emissions, water discharge, and waste management. Compliance reduces the risk of penalties and enhances corporate reputation. Moreover, environmentally responsible manufacturing resonates with today’s consumers, many of whom prioritize products made with eco-conscious methods. This growing market demand encourages brands to source tissue products from producers that demonstrate genuine commitment to sustainability.

In summary, modern tissue making machines deliver a powerful combination of operational efficiency and environmental stewardship. By embracing these technologies, manufacturers not only reduce their ecological footprint but also position themselves competitively in a market that values sustainable production as much as product quality.

While the upfront investment in modern tissue making machinery can be significant, the long-term benefits often lead to a rapid return on investment. Key factors influencing ROI include:

Lower energy and water costs due to efficiency gains

Increased production capacity and faster throughput

Reduced waste and fewer quality-related product returns

Enhanced product quality enabling access to premium market segments

Reduced maintenance costs and downtime

Many tissue manufacturers report payback periods within 1 to 2 years, making modernization a financially sound decision.

For manufacturers considering upgrading or installing new tissue making machines, the following approach helps ensure success:

Assessment: Conduct a thorough audit of current production capabilities, identifying bottlenecks and inefficiencies.

Goal Setting: Define clear objectives such as energy reduction, increased output, or quality improvement.

Customization: Work with machinery suppliers to tailor solutions to your specific raw materials, product types, and market needs.

Integration: Incorporate automation, monitoring, and control systems for seamless operation and data-driven management.

Training: Equip your workforce with the skills necessary to operate and maintain new equipment efficiently.

Continuous Improvement: Use data analytics to refine processes, detect issues early, and optimize performance over time.

Modern tissue making machines offer a compelling combination of efficiency, quality, and sustainability that is reshaping the tissue manufacturing industry. By embracing advanced technology and automation, manufacturers can reduce costs, increase production, and deliver premium products that meet evolving consumer and regulatory demands.

If you are looking to enhance your tissue production capabilities or explore tailored machinery solutions, Fujian Xinyun Machinery Development Co., Ltd. is a trusted partner with expertise in state-of-the-art tissue making equipment. Their team is ready to assist you in evaluating your needs, selecting the right machinery, and achieving your production goals.

For more information or to discuss how to upgrade your tissue manufacturing line, feel free to reach out to Fujian Xinyun Machinery Development Co., Ltd. Their knowledgeable staff can provide insights and guidance without any sales pressure—just professional advice to help you succeed.

1610 Enterprise Building, Wanan, Luojiang, Quanzhou, Fujian, China

Phone: +86-13685949824

Whatsapp: +86-13685949824

Email: elaine@xinyun-engine.com