Views: 214 Author: Site Editor Publish Time: 2025-08-29 Origin: Site

Tissue Paper Manufacturing

An In-Depth Guide to Machinery Used in Tissue Paper Making

Tissue paper has become an integral part of modern daily life, serving a variety of purposes from personal hygiene to household cleaning and food service. Behind this seemingly simple product lies a complex, highly engineered manufacturing process involving advanced machinery. Understanding the types of machinery used in tissue paper production is essential for those interested in industrial manufacturing, paper engineering, and sustainable production methods. This article explores in detail the primary machinery used in tissue paper making, their working principles, and their role in ensuring the consistent quality and efficiency of production.

Tissue paper production is a specialized branch of the paper industry that demands precision, speed, and efficiency. While traditional papermaking relied heavily on manual labor, modern tissue production integrates advanced mechanical systems to streamline every step, from raw pulp preparation to finished product packaging. These machines not only enhance productivity but also maintain consistent product quality, which is critical in meeting the expectations of both domestic and commercial consumers.

The machinery is designed to handle delicate fiber structures while achieving high-speed output. Modern tissue-making lines can produce thousands of rolls per day without sacrificing softness, strength, or absorbency. These qualities are controlled through adjustments in pulp refining, sheet formation, pressing, creping, and drying stages, all of which rely on specialized equipment. The transition from manual to fully automated systems has reduced human error, minimized waste, and improved environmental compliance. Additionally, integrating automation into tissue manufacturing enables real-time quality monitoring, allowing quick adjustments to maintain uniformity across production batches.

Tissue paper manufacturing consists of several sequential stages, each requiring specialized machinery. Below is an overview of the major steps and the primary machines involved:

| Production Stage | Machinery Used | Purpose |

|---|---|---|

| Pulp Preparation | Pulping Machine | Converts raw pulp or recycled fibers into uniform slurry |

| Refining | Refiners | Improves fiber bonding for strength and softness |

| Sheet Formation | Tissue Paper Machine Headbox | Distributes pulp evenly onto the forming wire |

| Water Removal | Press Section | Reduces moisture content mechanically before drying |

| Drying | Yankee Dryer & Hood | Dries the sheet to desired moisture while enhancing softness |

| Creping | Creping Blade | Creates texture, softness, and flexibility in tissue paper |

| Rewinding & Cutting | Rewinder & Slitter | Converts large parent rolls into smaller consumer rolls |

| Packaging | Automatic Packaging Machine | Wraps and seals finished tissue rolls for distribution |

The first stage in tissue paper production involves preparing the pulp, which may come from virgin wood fibers or recycled paper. The pulping machine is responsible for breaking down raw material into a fiber slurry. In virgin pulp processing, wood chips are chemically or mechanically pulped to separate cellulose fibers. In recycled pulp processing, recovered paper is de-inked and cleaned to remove contaminants before entering the main production line.

After pulping, the slurry undergoes refining in specialized refiners. This stage plays a crucial role in determining the final tissue paper’s softness and strength. Refining modifies fiber surfaces and fibrillation, improving bonding potential. The operator can adjust refining intensity to achieve the desired product characteristics. For instance, bathroom tissue requires maximum softness, while kitchen towels need more tensile strength. Modern refiners are designed to operate with energy efficiency in mind, reducing operational costs without compromising performance.

Once the pulp is refined, it is fed into the headbox of the tissue paper machine. The headbox evenly distributes the slurry onto a fast-moving forming wire, creating a continuous wet sheet. The uniform distribution of fibers at this stage is critical to avoiding defects such as holes, weak spots, or uneven thickness. The forming wire drains excess water by gravity and suction before the sheet moves to the pressing stage.

In the press section, mechanical pressure removes a significant portion of water from the sheet. Unlike other paper grades, tissue paper requires delicate handling to maintain bulk and softness, so pressing is lighter. This mechanical water removal is energy-saving because it reduces the load on the drying system. Modern press sections are engineered to balance moisture reduction with fiber preservation, ensuring the sheet retains its intended softness and absorbency.

Drying is one of the most energy-intensive stages in tissue manufacturing, and it is here that the iconic softness and flexibility are developed. The Yankee dryer—a massive, steam-heated cylinder—dries the sheet while pressing it gently against its smooth surface. Above the dryer, a high-temperature hood provides additional hot air to accelerate drying. This combination ensures uniform moisture removal and maintains the sheet’s bulk.

Once dried, the tissue sheet undergoes creping. A creping blade scrapes the sheet from the Yankee dryer surface, causing the fibers to wrinkle slightly. This process increases softness, flexibility, and absorbency. By adjusting blade angle and pressure, manufacturers can tailor the tissue paper’s feel, from silky smooth for facial tissues to more textured for paper towels. Creping also contributes to the sheet’s stretch properties, making it more durable during use.

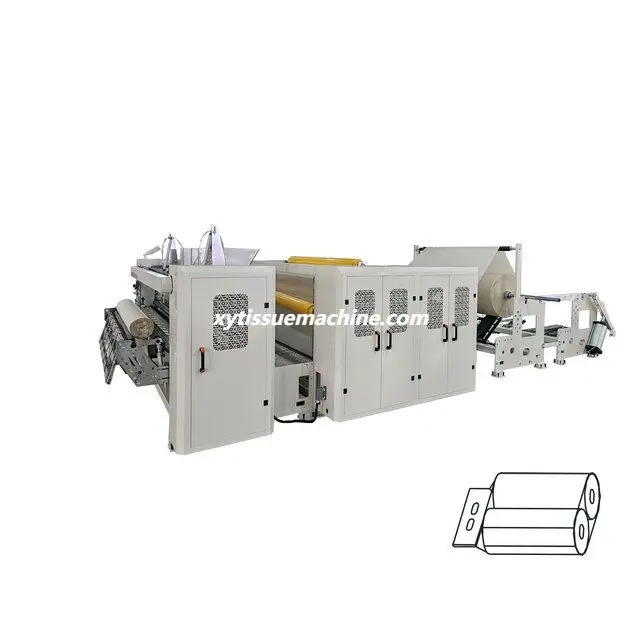

After creping, the tissue paper exists as large parent rolls, often several meters wide. These rolls are transferred to a rewinder, which unwinds, slits, and rewinds them into smaller logs suitable for consumer or commercial use. Precision control during rewinding ensures consistent roll length and diameter, avoiding waste.

The slitter then cuts the tissue logs into final roll widths, whether for household toilet tissue, jumbo commercial rolls, or kitchen towels. Each cut roll is passed through a packaging machine, which wraps and seals it for retail or bulk distribution. Automated packaging lines can apply single or multi-pack wrapping, apply barcodes, and ensure that every package meets shipping and storage requirements.

Modern tissue paper manufacturing heavily relies on automation to maintain efficiency and quality. Many production lines are equipped with sensors, scanners, and computer-controlled systems that continuously monitor fiber distribution, moisture content, and sheet thickness. Advanced automation can detect deviations in real time, allowing operators to adjust parameters immediately. This not only ensures uniform product quality but also minimizes production downtime and reduces waste.

Automation also contributes to safety. High-speed tissue machines can operate at over 2,000 meters per minute, so automated tension control, emergency stop systems, and enclosed cutting areas are critical to preventing accidents. In addition, integrating data analytics into production lines allows manufacturers to forecast maintenance needs, avoiding unexpected equipment failures and production interruptions.

With growing environmental awareness, machinery manufacturers are focusing on sustainable solutions. Energy-efficient drying systems, water recycling units, and low-emission hoods are becoming standard features in tissue production lines. Pulping machines are now designed to process recycled fibers with minimal loss in quality, enabling higher recycled content in tissue products without compromising softness or strength.

In addition, optimized cutting and packaging systems reduce material waste, and compact packaging designs help minimize transportation emissions. These innovations not only reduce environmental impact but also enhance competitiveness in markets where sustainability is a purchasing priority.

1. What is the most important machine in tissue paper manufacturing?

While all machines play vital roles, the Yankee dryer is often considered the most critical, as it directly influences softness, bulk, and drying efficiency.

2. Can tissue paper be made entirely from recycled materials?

Yes. With advanced pulping and refining machinery, tissue paper can be made from 100% recycled fibers while maintaining acceptable softness and strength levels.

3. How fast can modern tissue paper machines operate?

State-of-the-art tissue paper machines can run at speeds exceeding 2,000 meters per minute, producing thousands of rolls daily.

4. What role does automation play in tissue paper production?

Automation ensures consistent quality, reduces waste, enhances safety, and improves operational efficiency through real-time monitoring and control.

5. Is creping always necessary in tissue paper making?

Creping is essential for most consumer tissue products, as it creates the softness, flexibility, and absorbency that customers expect.

Tissue paper manufacturing is far more sophisticated than it appears at first glance. The journey from raw pulp to a neatly wrapped roll involves a precise combination of machinery, engineering expertise, and quality control. From pulping machines and refiners to Yankee dryers, creping blades, and automated packaging lines, each piece of equipment plays a specialized role in producing the soft, strong, and absorbent tissue paper that consumers use every day. As technology advances, these machines are becoming faster, more energy-efficient, and increasingly sustainable—ensuring that tissue paper production continues to meet the demands of a growing global market.

1610 Enterprise Building, Wanan, Luojiang, Quanzhou, Fujian, China

Phone: +86-13685949824

Whatsapp: +86-13685949824

Email: elaine@xinyun-engine.com